-40%

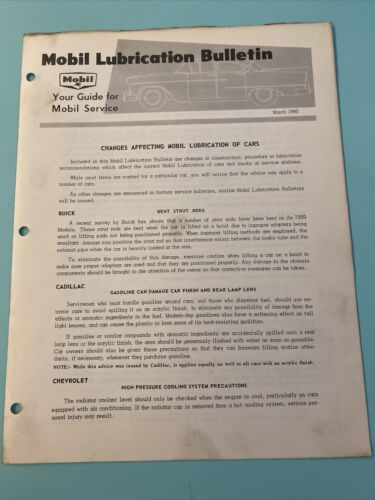

1960 March Mobil Oil Lubrication Bulletin Changes Buick Cadillac Dodge Valiant

$ 5.28

- Description

- Size Guide

Description

Very good condition. Spec sheet 4 pages.Mobil Lubrication Bulletin

Mobil

Your Guide for

Mobil Service

March 1960

CHANGES AFFECTING MOBIL LUBRICATION OF CARS

Included in this Mobil Lubrication Bulletin are changes in construction, procedure or lubrication

recommendations which affect the correct Mobil Lubrication of cars and trucks at service stations.

While most items are marked for a particular car, you will notice that the advice may apply to a

number of cars.

As other changes are announced in factory service bulletins, similar Mobil Lubrication Bulletins

will be issued.

BUICK

BENT STRUT RODS

A recent survey by Buick has shown that a number

strut rods have been bent on its 1959

Models. These strut rods are bent when the car is lifted on a hoist due to improper adapters being

used or lifting pads not being positioned properly. When improper lifting methods are employed, the

resultant damage may position the strut rod so that interference exists between the brake tube and the

exhaust pipe when the car is heavily loaded at the rear.

To eliminate the possibility of this damage, exercise caution when lifting a car on a hoist to

make sure proper adapters are used and that they are positioned properly. Any damage to the chassis

components should be brought to the attention of the owner so that corrective measures can be taken.

CADILLAC

GASOLINE CAN DAMAGE CAR FINISH AND REAR LAMP LENS

Servicemen who must handle gasoline around cars, and those who dispense fuel, should use ex-

treme care to avoid spilling it on an acrylic finish, to eliminate any possibility of damage from the

effects or aromatic ingredients in the fuel. Modern-day gasolines also have a softening effect on tail

light lenses, and can cause the plastic to lose some of its heat-resisting qualities.

If gasoline or similar compounds with aromatic ingredients are accidentally spilled onto a rear

lamp lens or the acrylic finish, the area should be generously flushed with water as soon as possible.

Car owners should also be given these precautions so that they can forewam filling station atten-

dants, if necessary, whenever they purchase gasoline.

NOTE:- While this advice was issued by Cadillac, it applies equally as well to all cars with an acrylic finish.

CHEVROLET

HIGH PRESSURE COOLING SYSTEM PRECAUTIONS

The radiator coolant level should only be checked when the engine is cool, particularly on cars

equipped with air conditioning. If the radiator cap is removed from a hot cooling system, serious per-

sonal injury may result.

----------- 3 -----------

The cooling system fluid level should be maintained one inch below the bottom of the filler neck

of the radiator with a cold cooling system, or at the bottom of the filler neck when the system is warm

It is very important that the correct fluid level be maintained. The sealing ability of the radiator can

is affected when the coolant level is too high.

Since 1958, Chevrolet passenger cars have been equipped with a 13 pound pressure radiator cm

which permits safe engine operation at cooling system temperatures of at least 243 F. This is because

the coolant boiling point is increased approximately 3°F per pound of system pressure.

When the radiator cap is removed or loosened, the system pressure drops to atmospheric, and the

heat which had caused water temperature to be higher than 212 F, will be dissipated by conversion of

water to steam during a few moments of violent boiling.

As the steam may form in the engine water passages, it will blow coolant out of the radigtor

upper hose and top tank, necessitating coolant replacement and usually causing customer complaints.

It should be pointed out to station attendants and passenger car owners that with a pressurized

cooling system, engine operating temperatures are higher than the normal boiling point of water

(212•F). Operating temperatures of 212 F or higher improve the operating efficiency of the engine but

necessitate precautions.

Upon complaints of repeated coolant loss, the pressure radiator cap and seat should be checked

for sealing ability. Also, the cooling system should be checked for loose hose connections, defective

hoses, gasket leaks, etc. If you are confronted with this problem, we suggest that a pressurized cool-

ing system tester be used. Such testers gre available from many automotive parts distributors and are

manufactured by various companies. The tester is adaptable for checking the radiator pressure cap

and the cooling system for pressure leaks.

CHRYSLER, PLYMOUTH

AIR CLEANER SERVICE

Chrysler and Plymouth have issued service bulletins whic

instructions in Service Manuals and Lubrication Charts concerning service of the carburetor air cleaner

filter elements used on their 1957, 1958, 1959, and 1960 cars.

supersede and cancel all previous

They have determined that using compressed air to blow out the carburetor air cleaner filter

element provides an effective method of removing excess dust and dirt from the filter, without the

possibility of damaging the seals or breaking the paper. Therefore, the following procedure for cleaning

and servicing the carburetor air cleaner filter is recommended:

1. Remove the filter element from the air cleaner housing.

2. Hold the air nozzle approximately two inches from the inner screen and blow

outward through the filter to remove loose dirt.

Clean the carburetor air filter elements at least every 5000 miles, and install a new filter element

every 10,000 miles. When unusual or severe driving conditions are encountered, more frequent servicing

of the air cleaner filter may be required.

CORVAIR

LIFTING CAR

A Corvair can be satisfactorily lifted by attaching hooks to the holes in the bumper brackets.

When this procedure is used, adequate protection must be given to the chrome bumpers and body sheet

metal. Position nylon straps or other protective padding between the lifting chains and the body to

minimize the possibility of damage to the body sheet metal and bumpers.

DODGE

CHECK FOR DAMAGED RUBBER BUMPER

Field experience has shown that damage to the front suspension of 1959 Dodge cars, K, L and M

-2-

----------- 3 -----------

Series, can generally be associated with the rubber jounce bumper on the frame having been knocked

off. When this bumper is not in place, movement of the ball joint is not maintained within its limits

and damage may result.

Every time the chassis is lubricated, the jounce bumpers should be inspected for correct instal-

lation and positioning.

If the jounce bumper has been knocked off, it should be replaced and the ball joint inspected.

If inspection reveals that the ball joint has been damaged, it should be replaced.

LINCOLN

LUBRICANT FOR POWR - LOK AXLE

Our Research Department has road tested Mobilube GX 90 in Lincoln cars equipped with POWR – LOK

limited slip axles and results show that it gives satisfactory performance. In view of the test results

obtained, we now recommend Mobilube GX for refilling these axles after draining as well as for top-

ping - up.

MERCURY

AUTOMATIC TRANSMISSION VENT TUBE ASSEMBLIES

All PBL transmission assemblies manufactured after approximately 5-1-59 and PBM transmission

assemblies manufactured after 5-8-59 incorporate a new breather (vent) tube, replacing the previous

flutter cap vent assembly. The new breather tube provides a larger transmission vent, reducing the

possibility of pressure build-up within the transmission. This minimizes the possibility of fluid "spill-

over" from the filler tube under severe operating conditions.

The vent opening in the new transmission cases has been changed from a 1/8-27 pipe thread to

a 1/2-20 thread to accomodate the new breather tube and attaching nut.

All transmission cases used to service 1951 – 1960 Mercury cars have been changed to accomo-

date the new breather tube.

The benefits of increased venting can also be obtained in all existing 1951 thru 1959 trans-

missions (except PBB and PBE models) by installing a new "service only" breather tube kit, part

number B9MY - 7A246-B. This kit contains the following parts:

B9AP-7A245-A – Breather Tube and Nut Assembly

373111-S

Clip

373125-S

Elbow Fitting

NOTE:- The old flutter cap vent assembly will not fit on the new cases.

MERCURY

LUBRICATION OF POWER STEERING VALVE

When lubricating the power steering valve on Mercury cars, the two clamp screws retaining the

protective boot on the sleeve end of the valve should be removed to allow escape of the chassis

lubricant. Failure to loosen the clamp can cause the boot to rupture, destroying its sealing capacity.

PLYMOUTH

SURE - GRIP DIFFERENTIAL CHATTER

A service procedure has been developed by Plymouth to correct Sure-Grip differential chatter on

turns. This procedure includes flushing contaminants and foreign matter from the axle for they are

often the cause of chatter in Sure-Grip differentials.

Emphasis is made on the importance of blowing out the axle housing with compressed air to re-

move all traces of the solvent used for flushing. If this is not done, lubricant dilution may be great

enough to lower the lubricating properties of the axle oil below their necessary level of effectiveness,

- 3 -

----------- 4 -----------

resulting in gear tooth scoring. The procedure is as follows:

1. Operate car until axle housing is warm when touched (approximately 100•F).

This approximates 10 minutes of driving at 40 mph.

2. Remove drain and filler plugs and allow axle to drain for at least five minutes.

3. Replace drain plug. Fill axle to bottom of filler plug hole with naphtha, mineral

spirits, or other suitable solvent.

4. Rotate the rear wheels by hand for five minutes, alternating direction of rotation.

5. Remove axle drain plug. Allow fluid to drain.

6. IMPORTANT:- Insert air hose into filler plug hole. Blow out axle with com-

pressed air for 15 minutes, or until solvent odor is no longer noticeable. This is

necessary to evaporate as much of the retained solvent as possible and prevent

dilution of the fresh lubricant with the solvent used.

7. Flush the axle with at least two pints of Mobilube GX 90. Allow to drain at

least five minutes.

8. Replace drain plug and tighten. Fill axle to correct level with Mobilube GX 90.

Replace filler plug and tighten.

The car should be driven at least 10 miles before checking for chatter. Time

must be allowed for the fresh lubricant to become worked between the clutch

discs of the Sure- Grip unit. As mileage is accumulated, retained contaminants

will be diluted by the fresh lubricant making the unit less and less susceptible

to chatter.

VALIANT

OIL FILTER REPLACEMENT

When changing the oil filter on a Valiant engine, extreme care should be exercised to prevent ex-

cess oil from dripping on the steering idler arm bushing. This bushing is made of natural rubber and

will deteriorate in the presence of oil.

The idler arm is located directly below the filter, and due to the angle of the oil pump mounting,

a small quantity of oil will flow from the pump body when the filter is removed.

To prevent this condition it is advised that a shop cloth be wrapped around the pump when re-

moving the filter cartridge.

If oil is accidentally spilled on the idler arm bushing it should be wiped dry immediately.

STUDEBAKER

CHECKING TRANSMISSION LUBRICANT LEVEL

When draining and refilling the transmission with overdrive on 1958-1960 Studebaker cars, the

drain and filler plugs in each housing must be removed. Each housing should be drained and refilled

as a separate unit.

When checking the lubricant le vel, remove the filler plugs from both housings and add lubricant

to each housing, when necessary.

If this procedure is not followed, there is danger of operating with insufficient lubricant after the

lubricant level has stabilized between both sections.

Mobil

PRODUCTS DEPARTMENT

150 EAST 42 STREET, NEW YORK 17, N.Y.